Revised 12/29/2025

LIMESTONE CALCINED CLAY CEMENT – LC3

AN OVERVIEW

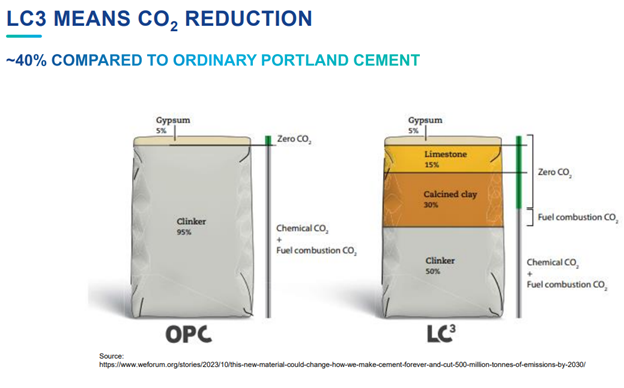

The process of producing clinker in Ordinary Portland Cement (OPC) is responsible for 85-90% of carbon emissions from concrete, and concrete is responsible for 6-8% of annual global carbon emissions. There are novel cements promising near zero carbon emissions in development including Brimstone and Sublime, but all of these cements have problems with scaling to meet the growing global concrete consumption needs. When compared to Portland Cement with no SCMs, LC3 can reduce carbon emissions by about 40%.

FIRST, A FEW WORDS ABOUT ORDINARY PORTLAND CEMENT (OPC)

OPC is the dominant cement used globally. It is a blend of limestone, clay, and gypsum. A mixture of limestone and clay is heated in rotary kilns at 1450 C to create “clinker” and is then ground with gypsum to form cement. About 46% of carbon emissions are due to the energy used, and about 53% are due to the release of CO2 from the limestone in the rotary kiln.

PROCESS DIAGRAM FOR OPC:

TYPES OF CEMENT

There are three cement types and Type I cement is for general use and is the type used in this discussion. When one or more Supplementary Cementitious Materials (SCM) are added to OPC, this is called a blended cement. The most common blended cements are Type IL (Portland Limestone Cement or PLC), Type IP (Portland pozzolan cement or PPC), and Type IS (Portland blast-furnace slag cement or PSC). LC3 cement is classified as a ternary blended cement, which means it has more than one SCM, limestone and calcined clay.

OPC vs LC3 CEMENT

Here is a simple graphic that illustrates the differences in composition of these two cements:

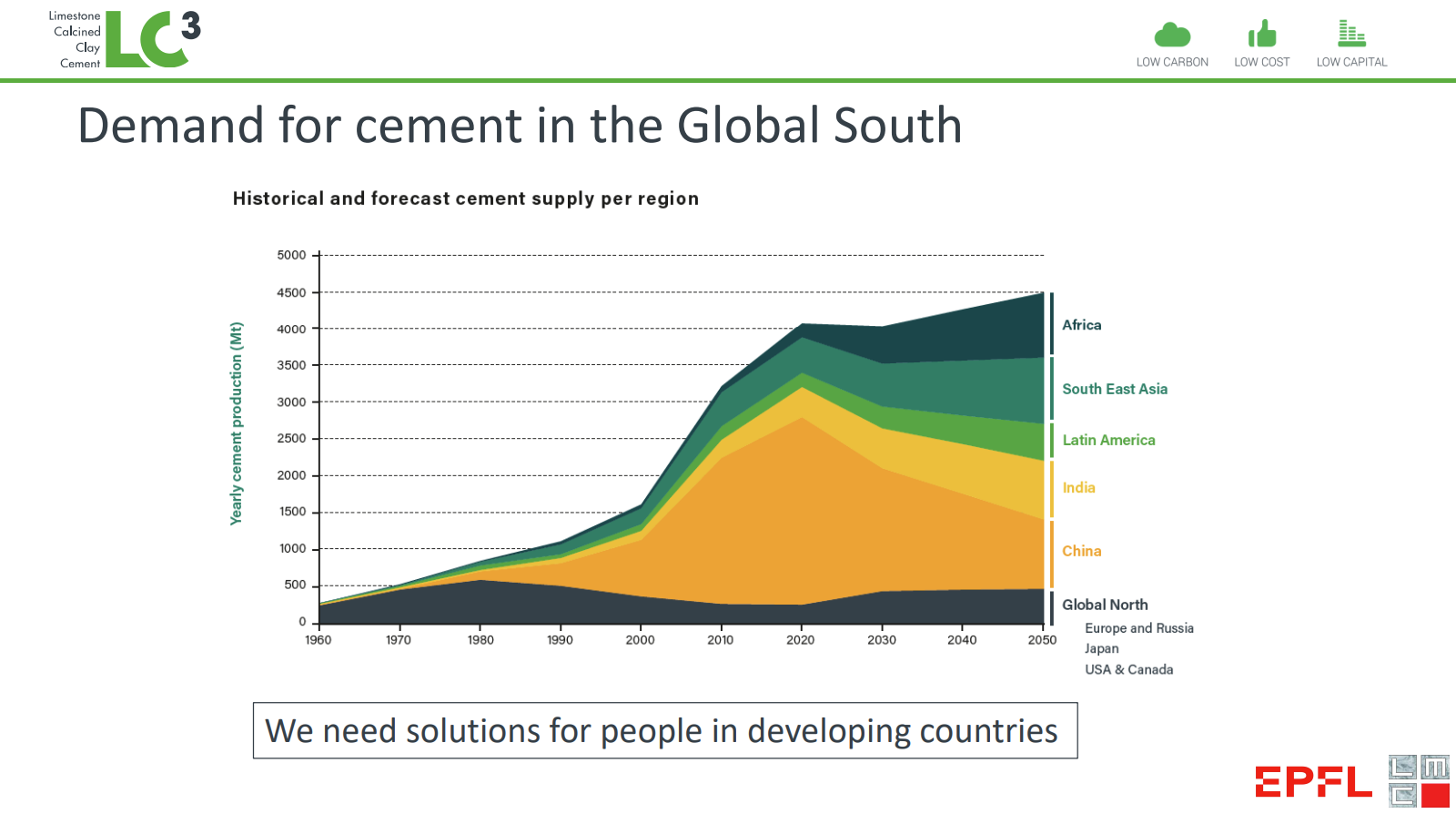

LC3 CEMENT AND THE GLOBAL SOUTH

Professors Karen Scrivener of the Ecole Polytechnique Federale de Lausanne (EPFL) and Fernando Martirena (UCLV, Cuba) began exploring calcined clay in 2004-2005. The Swiss institute that formally developed LC3 (EPFL) is also supported by the Swiss Agency of Development and Cooperation (SDC) whose mission is to “alleviate suffering and poverty worldwide, promote peace and security, and to protect the environment”. LC3 cement is currently being produced commercially in Colombia, India, Ghana, Malawi, France, and Denmark. The rapid development of LC3 in the global south is due to the efforts and support by the SDC. Over 90% of global cement production is concentrated in the Global South with the largest expected growth in Asia and Africa.

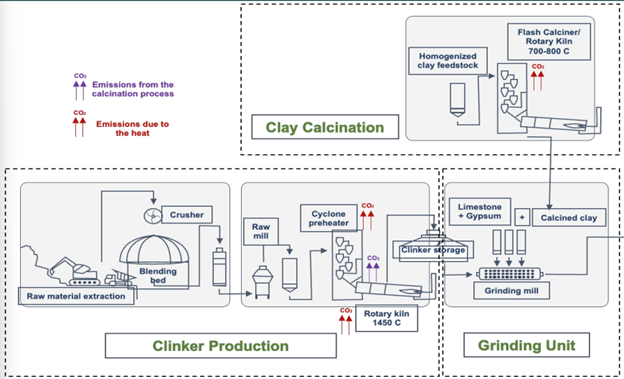

PROCESS DIAGRAM FOR LC3:

This diagram shows that the main differences in the production of LC3 vs OPC are the addition of a calcined clay (using a kalonitic clay), and the replacement of OPC clinker by up to 50% with the calcined clay. This results in a reduction of embodied carbon emissions of about 40%. LC3 can be made at existing OPC cement plants by adding equipment to handle, calcine, and mill the clay.

A product called LC2 consisting of the SCM products used in LC3 can be produced at a separate plant, bagged, and shipped to a readymix plant to mix with bags of OPC.

Chart is from a 2023 RMI conference: “Scaling Limestone Calcined Clay Cement (LC3): Learnings from the First Movers”, presented by Radhika Lalit, Principal of Cement and Concrete Team at RMI. Ref [2]

LC3 IN THE U.S.

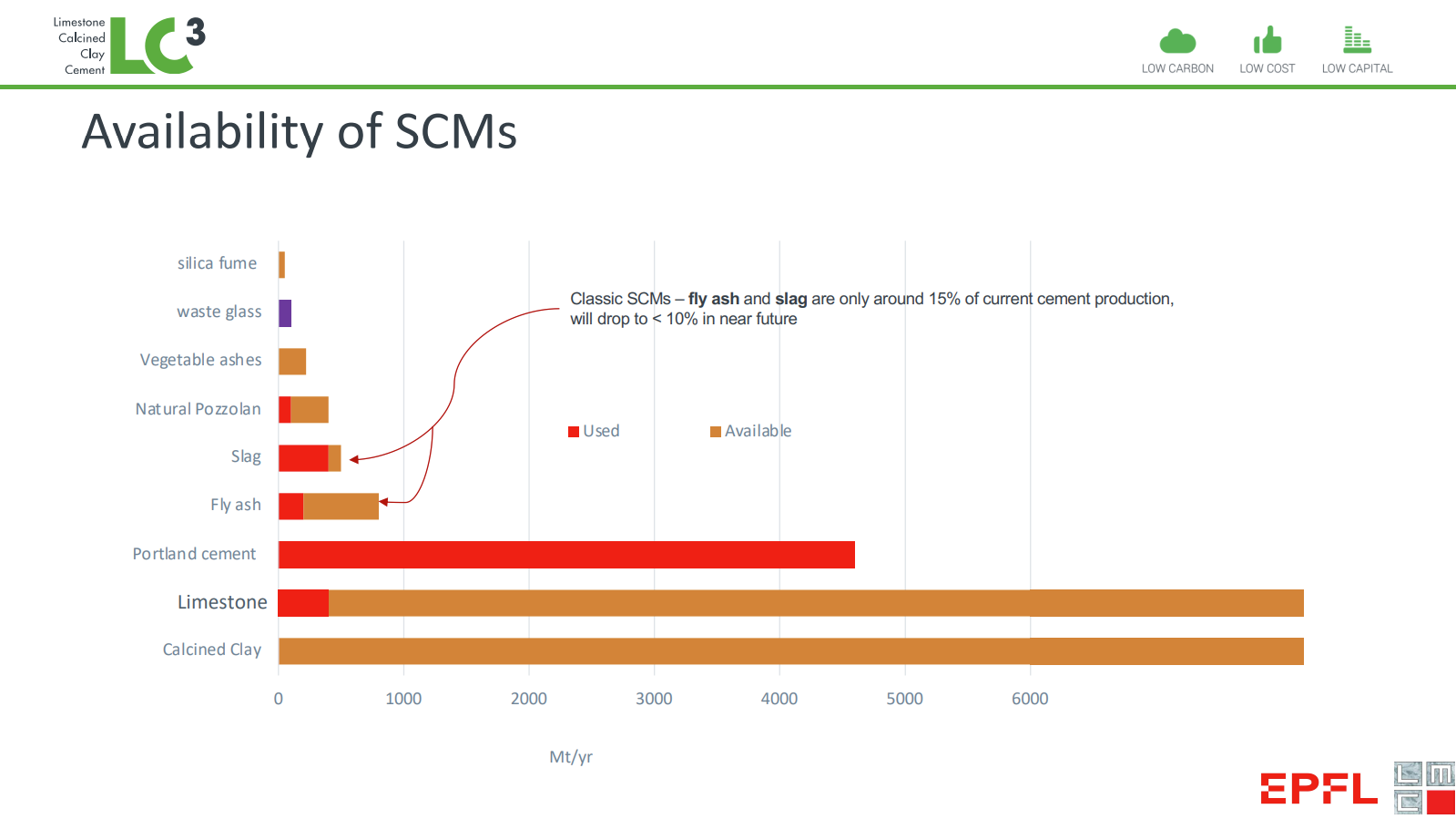

LC3 cement production in the U.S. is currently being pursued by Argos in Texas and the Eastern half of the U.S., Ash Grove in Nebraska, Missouri and Texas, Purebase in California, Summit Materials in Texas, and by Roanoke Cement in Virginia. In Colorado the cement companies to watch for future LC3 cements are Holcim (EcoPlanet) and Cemex. The SCMs currently in use in the U.S. include Fly Ash and steel slag. The amount of fly ash available to the construction industry is limited and getting smaller with the movement away from coal-fired power generation. Steel slag is available only in certain parts of the U.S. The ability to produce calcined clay plus limestone as an SCM has the potential to make it an important SCM for the future. The raw material resources are currently available and can be scaled. The graph below shows the relative global availability of SCMs.

COMPARISON OF KEY ATTRIBUTES OF OPC vs LC3

LC3-50 = 50% clinker.

40% less CO2 emissions

Similar strength

Better chloride resistance

Resistant to alkali silica reaction

Creep is significantly lower

Generally lower costs “LC3, a blended cement composed of only 50% clinker, can successfully replace OPC with significantly lower production costs and CAPEX.”Ref[1]

GWP is 2/3 of Portland Limestone Cement (Type IL)

GWP per FUTURECEM (Belgium) 2025 EPD = 525 kgCO2e/1,000 kg

REFERENCES

[1] Financial Attractiveness of LC3; Cemintis, EPFL, Swiss Agency for Development and Cooperation SDC; K. Scrivener, A. Dekeukelaere, F. Avet, L. Grimmeissen

[2] Webinar: Scaling Limestone Calcined Clay Cement (LC3): Learnings from the First Movers, RMI, EPFL, 2023

[3] Hasanbeigi, Ali, Pavitra Srinivasan, Hellen Chen, and Nora Esram. 2024. Adoption of Limestone Calcined Clay Cement and Concrete in the U.S. Market. Washington, DC: ACEEE and GEI. www.aceee.org/research-report/i2401

[4] Limestone Calcined Clay Cement, https://lc3.ch/about-lc3/